SL-SA-S Foaming Stabilizer is used primarily as foaming stabilizer to enhance half-life in foaming-based drilling fluids.

An Introduction to Cementing Additives:

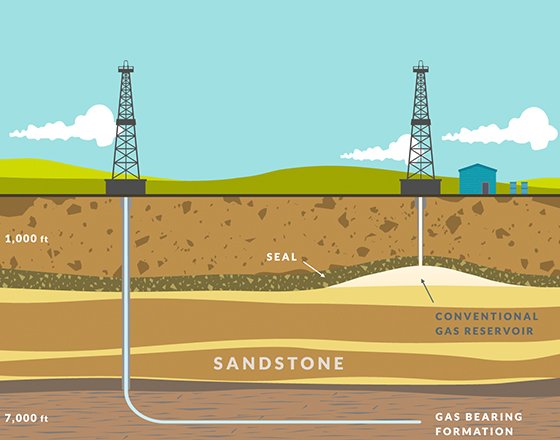

Cementing is a crucial step in the oil and gas extraction process. It involves injecting cement slurry into the annular space between the wellbore and the casing to isolate the formation, strengthen the wellbore wall and provide good support. In order to ensure that the cement slurry can meet the performance requirements under specific conditions, it is often necessary to add various admixtures to adjust its physical and chemical properties. These admixtures constitute the so-called "cementing admixture system", which is of great significance to improving cementing quality and reducing costs.

Cementing can achieve the following purposes

Fixing and protecting casing

All casings installed during drilling must be fixed by cementing operations. In addition, the cement stone outside the casing can reduce the compression of the formation on the casing and protect the casing

Protecting high-pressure oil and gas layers

When drilling into high-pressure oil and gas layers, blowout accidents are prone to occur. It is necessary to increase the density of the drilling fluid to balance the formation pressure. After drilling the high-pressure oil and gas layers, casing must be installed and cemented to protect the high-pressure oil and gas layers

Seal off serious leakage layers and other complex layers

When drilling into serious leakage layers, the method of reducing the density of the drilling fluid and adding plugging materials can be adopted. After drilling the serious leakage layer, casing must also be installed and cemented, and the leakage layer must be sealed to prevent it from affecting the subsequent drilling.

-

Foaming Stabilizer SL-SA-S

more+

more+ -

Foaming Agent SL-FA-S

Foaming agent SL-FA-S is a chemical product composed of Olefin Sulfonates, thermal stability could reaches 150 ℃.

more+ -

High Temperature Retarder for Oil Well Cement CMT-107

CMT-107 can stick on the surfaces of cement hydrate to inhibit contacting between cement and water, also stick on the surfaces of crystal nucleons to prevent their enlarging. So it can retard hydrating of cement slurry.

more+ -

Middle Temperature Retarder for Oil Well Cement CMT-106

CMT-106 can stick on the surfaces of cement hydrate to inhibit contacting between cement and water, also stick on the surfaces of crystal nucleons to prevent their enlarging. So it can retard hydrating of cement slurry.

more+ -

Retarder for High Temperature Oil Well Cement Cement CMT-105

CMT-105 dissolves in water quickly owing to its strong hydrophilic property.It can absorb on the surfaces of the cement slurry hydrate to inhibit contact with water and chelate with Ca2+ to prevent crystal nucleus forming early. Therefore, it can retard thickening time.And,it can enhance the last strength of the cement stone because C3A shows weak adsorption performance.

more+ -

High Temperature Retarder for Oil Well Cement CMT-104

CMT-104 can stick on the surfaces of cement hydrate to inhibit contacting between cement and water, also stick on the surfaces of crystal nucleons to prevent their enlarging. So it can retard hydrating of cement slurry

more+ -

Fluid Loss Control Additive for Oil Well Cement CMT-103

CMT-103 belongs to pure polymerization and water-soluble agent , reduces the slurry cake permeability by the aggregation of water-soluble high polymer molecular chain. And a variety of functional groups are introduced into the polymer to enhance the anti high temperature property and salt resistance.

more+ -

Fluid Loss Control Additive for Oil Well Cement CMT-102

CMT-102 reduces the slurry cake permeability by the aggregation of water-soluble high polymer molecular chain. And a variety of functional groups are introduced into the polymer to enhance the anti high temperature property .

more+ -

Dispersing Agent for Oil Well Cement CMT-101

CMT-101 drag reducing agent (dispersing agent) can adjust the electric charge on the surfaces of cement particles to get proper cement rheology. As a result, it can reduce pump pressure, enhance drilling efficiency and used in construction easily.

more+ -

SL-LUBE D Lubricant SL-LUBE D

The friction between the drill string and the formation during drilling can lead to a series of problems such as excessive torque and drag pressure, which in turn affects the drilling speed and drilling safety.

more+ -

Polyamine Shale Inhibitor SL-AP01

The polyamine inhibitor is a newly developed high-performance shale inhibitor for water-based drilling fluids, belonging to the modified polyamine category.

more+ -

Fluid Loss Control SL-FL01

During the drilling process, because of pressure difference, the water in the drilling fluid will inevitably filter through the well wall into the formation, causing water loss in the drilling fluid.

more+